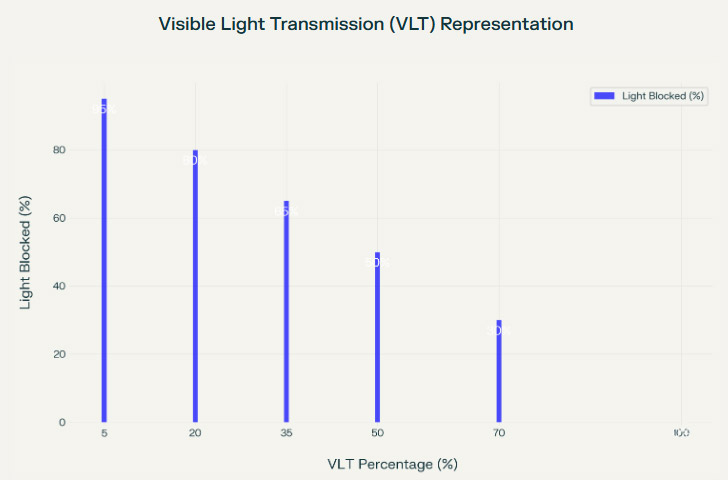

Visible Light Transmission (VLT) measures the percentage of visible light that passes through a material, such as glass or film. Higher VLT percentages allow more light to pass through, making the material appear clearer. Lower VLT values reduce brightness and provide greater shading or privacy.

Here we explore the science, measurement, and practical implications of VLT.

The Science of Visible Light and Transmission

Defining Visible Light Spectrum

The visible light spectrum represents the portion of the electromagnetic spectrum that human eyes can detect. Typically, humans perceive wavelengths ranging from approximately 380 to 700 nanometers. This narrow band of radiation is detected by cone-shaped cells in our eyes that act as receivers tuned to these specific wavelengths. The visible spectrum includes all the colors we perceive, from violet (shortest wavelength) to red (longest wavelength) [1].

What Is Visible Light Transmission?

Visible Light Transmission, commonly abbreviated as VLT, refers to the amount or percentage of visible light that passes through a material or medium. In technical terms, it represents the ratio of transmitted luminous flux to incident luminous flux, expressed as a percentage. This measurement indicates how transparent or opaque a material appears to the human eye.

When light interacts with a material, three primary phenomena can occur:

- Visible Light Transmission (VLT): Light passing through the material

- Visible Light Absorptance (VLA): Light being absorbed by the material

- Visible Light Reflectance (VLR): Light bouncing off the surface of the material

The sum of these three components accounts for 100% of the incident light.

Types of Light Transmission

Light can be transmitted through materials in different ways, depending on the nature of the material:

Regular Transmission

Regular transmission (also called direct transmission) occurs when parallel light is deflected at an angle in the direction of propagation through a material with a smooth surface and uniform internal texture. Materials exhibiting regular transmission allow you to clearly see images through them. For example, clear glass primarily demonstrates regular transmission [2].

Diffuse Transmission

Diffuse transmission happens when light passes through materials with rough surfaces or non-uniform internal structures, causing the light to scatter in multiple directions. Materials like frosted glass, translucent plastics, or milky white surfaces exhibit diffuse transmission. When looking through these materials, images appear blurred or distorted because the transmitted light is scattered rather than passing directly through.

Measuring and Calculating VLT

Measurement Techniques

Visible Light Transmission is typically measured using specialised instruments called photometers or VLT meters. These devices measure the intensity of light before and after it passes through a material. Modern VLT meters can provide quick and accurate readings for various materials, from window films to optical lenses.

High-accuracy VLT meters are designed specifically for optical transmittance tests of various materials including lenses, glass, coating materials, and organic material paints. These instruments typically feature:

- Colour LCD displays for easy reading

- Capability to measure even ultra-small sized materials

- Fast and accurate test results

Mathematical Calculation

The formula for calculating light transmittance is:

- Light transmittance = (transmitted light intensity / incident light intensity) × 100%

- Additionally, optical density (OD), which is related to transmittance, can be calculated as:

- OD = log10(1/transmittance)

This logarithmic relationship provides another way to express how effectively a material blocks light.

Applications of VLT Measurements

Window Films and Glass

VLT is particularly important in the window film industry, where it serves as a critical specification for products designed to reduce heat, glare, or fading in interior spaces. The more visible light a window film blocks (lower VLT percentage), the higher its performance in these areas. Window films come in various grades and VLT levels, allowing consumers to choose how much light will pass through based on their specific needs.

Eyewear and Sunglasses

In the eyewear industry, VLT helps categorise sunglasses and determines their suitability for different lighting conditions. Lower VLT percentages indicate darker lenses that allow less light to pass through, making them more suitable for very bright conditions like snowy roads on sunny days. Higher VLT percentages result in lighter lenses more appropriate for less intense lighting situations.

Automotive Applications

VLT measurements are crucial in the automotive industry for verifying car window tinting compliance with regulations. Law enforcement officers often use portable tint meters for roadside inspections to ensure vehicles meet legal standards for window transparency.

Construction and Building Materials

In construction, VLT measurements help evaluate building window films and glass materials to ensure they meet architectural specifications and building codes. These measurements are essential for balancing natural light admission with energy efficiency and occupant comfort.

Factors Affecting VLT

Several factors influence the VLT of a material:

Material Properties and Thickness

The composition and thickness of a material significantly impact its VLT. Generally, thicker materials of the same type will transmit less light than thinner ones. The molecular structure of the material also determines how much light passes through, gets absorbed, or reflects back.

Tinting and Coatings

Tints and coatings applied to glass or lenses can dramatically alter VLT properties. Darker tints have lower VLT values, while lighter tints have higher values. Special coatings can selectively filter certain wavelengths while allowing others to pass through, which is particularly useful in specialised applications like laser safety glasses.

Polarization and Special Treatments

Polarization and other special treatments can affect VLT while providing additional benefits such as reduced glare. These treatments can modify how light is transmitted through a material without necessarily changing its apparent darkness or colour.

VLT Categories and Standards

In many industries, VLT is categorized into standardised ranges to help consumers make appropriate choices:

For sunglasses and optical filters, common categories include:

- Category 0: 80-100% VLT (very light or clear)

- Category 1: 43-80% VLT (light tint)

- Category 2: 18-43% VLT (medium tint)

- Category 3: 8-18% VLT (dark tint, suitable for bright sun conditions)

- Category 4: 3-8% VLT (very dark, not suitable for driving)

What is the VLT rating of a window?

The Visible Light Transmission (VLT) rating of a window refers to the percentage of visible light that passes through its glazing system. In Australia, VLT is typically expressed as a fraction or percentage, ranging from 0 (no light transmitted) to 1 (maximum light transmission). Most double-glazed windows in Australia have VLT ratings between 0.3 and 0.7, meaning they allow 30% to 70% of visible light to pass through.

A higher VLT rating indicates more natural light entering the space, which enhances brightness and reduces reliance on artificial lighting. However, lower VLT ratings are often used for glare control or privacy purposes. Factors affecting a window’s VLT include the type of glass, coatings (such as Low-E coatings), frame design, and insect screens.